Why Combined Heat and Power?

CHP reduces carbon emissions and fuel consumption significantly compared to the separate means of conventional generation via a boiler and power station.

Combined Heat and Power is often the measure that offers the most significant opportunity to reduce energy costs, improve environmental performance and meet energy efficiency requirements.

Environmentally Friendly

Based on the total energy generated, cogeneration plants typically cut NO2 and CO2 emissions by almost 50% compared to thermal power plant/boiler systems, while complying with the strictest emissions regulations.

Our aim is to lower the emissions produced (CO and CO2) which will be better for us and for the environment.

Will CHP save money?

As a rule, CHP units need to run for at least 4,000 hours per year to be economically viable.

Using CHP, a proportion of an application’s electricity requirement is generated by mains fed gas, reducing the cost of energy used.

Typical prices are 7-12 p per kWh for mains electricity, but only 2-4p per kWh for mains gas.

Gas Safe Registered

We want to ensure the highest level of customer safety, so we are gas safe registered.

This is to ensure every gas installation or conversion is produced to run safely and efficiently, and to provide the highest possible level of reliability for our customers.

Case Studies

Combined Heat and Power Solution Saves University USD $1,000 a day

The CHP solution serves as the primary heat source for the Wesleyan University athletic facility. The 676 kilowatt-electric kWe system provides hot water for basic services, keeps the pool temperature at 80 degrees Fahrenheit (27 degrees Celsius) and heats the hundreds of gallons of 150-degree (66 degrees Celsius) water needed for the building’s ice rink. It also provides 90 pounds per square inch (psi) (6.2 bar) steam, generated from the engine’s exhaust, to the campus.

CHP Solution Helps University Meet Carbon Emissions Goals

As part of a carbon reduction program, the University of Wolverhampton had been operating two combined heat and power (CHP) systems. These two units provide heat and power to multiple buildings across the campus. It is estimated that the system will reduce the University’s carbon emissions by 1,000 tons per year, with an annual savings of $352,000 (£228,600) per year.

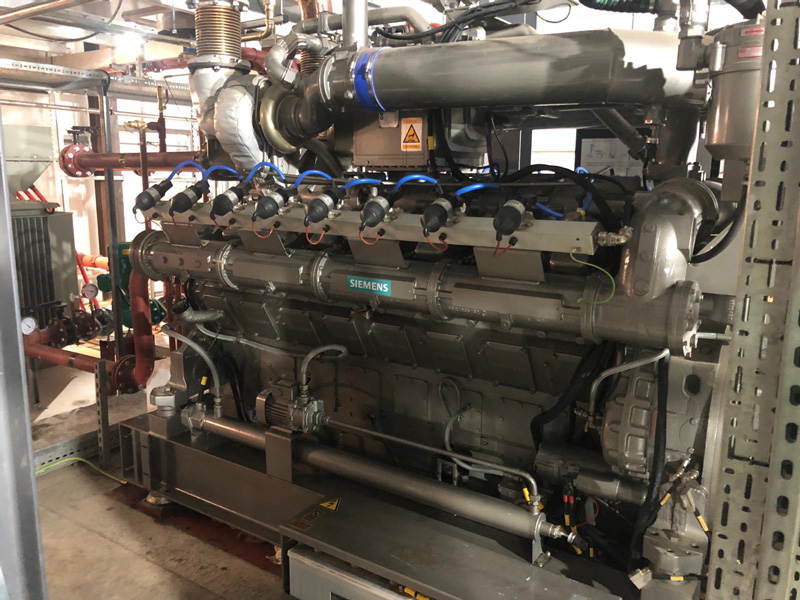

What does a CHP system contain?

Typically a GF Genovate small scale (100kWe to 2MWe) CHP unit will be supplied packaged and ready for installation. This does not mean to say that it is an off the shelf product – each unit is tailored to meet your very specific site requirements.

The package will contain:

- The internal combustion engine which produces the heat and drives the generator

- The generator to produce the electricity

- The heat recovery equipment to provide heat in the right format for your site

- And pipework, valves and controls